Programmable Logic Controllers

Barrett Electric specializes in Allen-Bradley Programmable Logic Controllers. The MicroLogix line allows for us to fill a large variety of customer applications, from powerful, large-scale applications, to simple and concise without the need for extraneous spending.

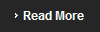

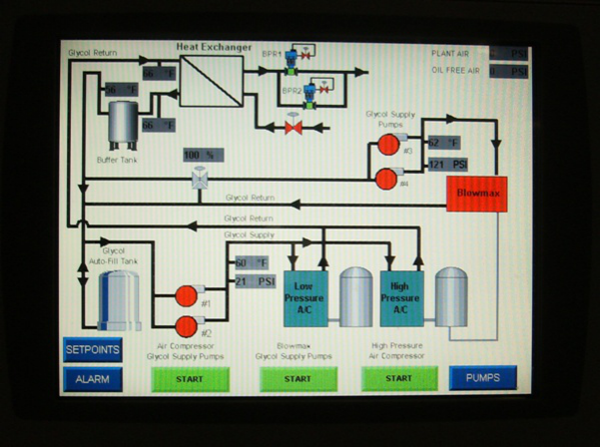

We do business with several electrical contractors who use our skills to complete work for their customers. A large bottling customer was installing a new bottling line that included ammonia/glycol heat exchangers, control valves, air compressors and a bottling line. The process consisted of an ammonia cooling loop cooling a glycol loop that in turn circulated through VFD controller pumps to manage the cooling of high pressure and low pressure plant air compressors and a low max bottle forming machine. We provided a control panel design based on an engineered scope of work that include Allen Bradley PLC and HMI controlled pumps, valves, solenoids, system temperature and pressure sensors to complete a controlled cooling package.

|

|

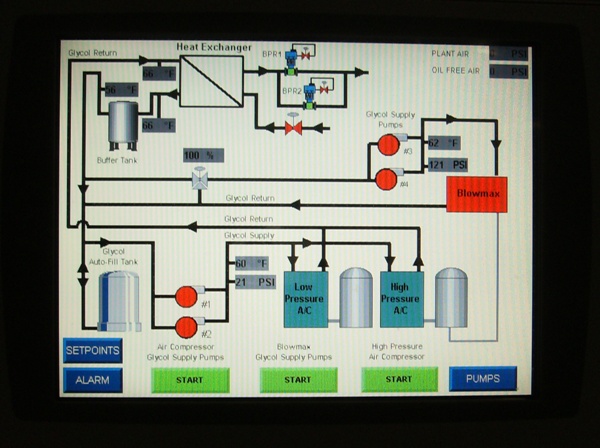

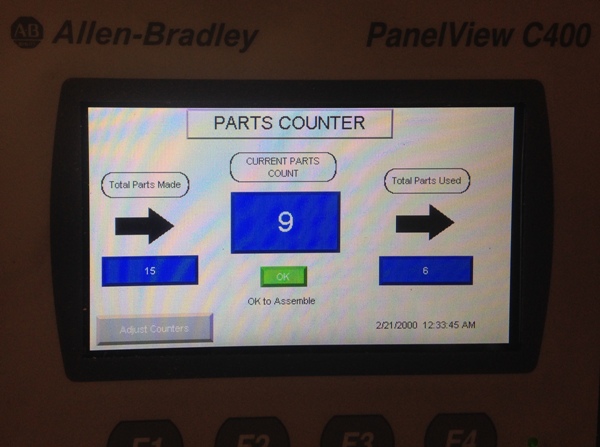

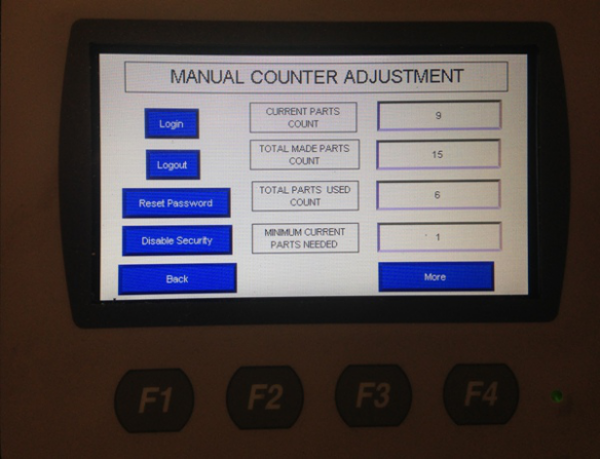

A client expressed a need for a system of counting goods produced and placed into a container, subtracting goods that are removed from the container, and a total number of goods produced regardless of whether they were removed or not. The system needed to be retrofit, and to not hinder production.

Barrett Electric engineered the project with specifications from the client (availability of resources, sizing, and necessary functions). We designed and built a panel capable of supporting the system, designed and built the program for the controller to use, and designed and built the peripherals necessary to complete the task. We then installed the system in our customers location, along with giving relevant employees the necessary prints and designs needed to run and repair the system. As a full service contractor, we are available to repair or adjust the system as time and function necessitates. Our intimate knowledge of the system allows us to repair much more efficiently and effectively.

|

|

|

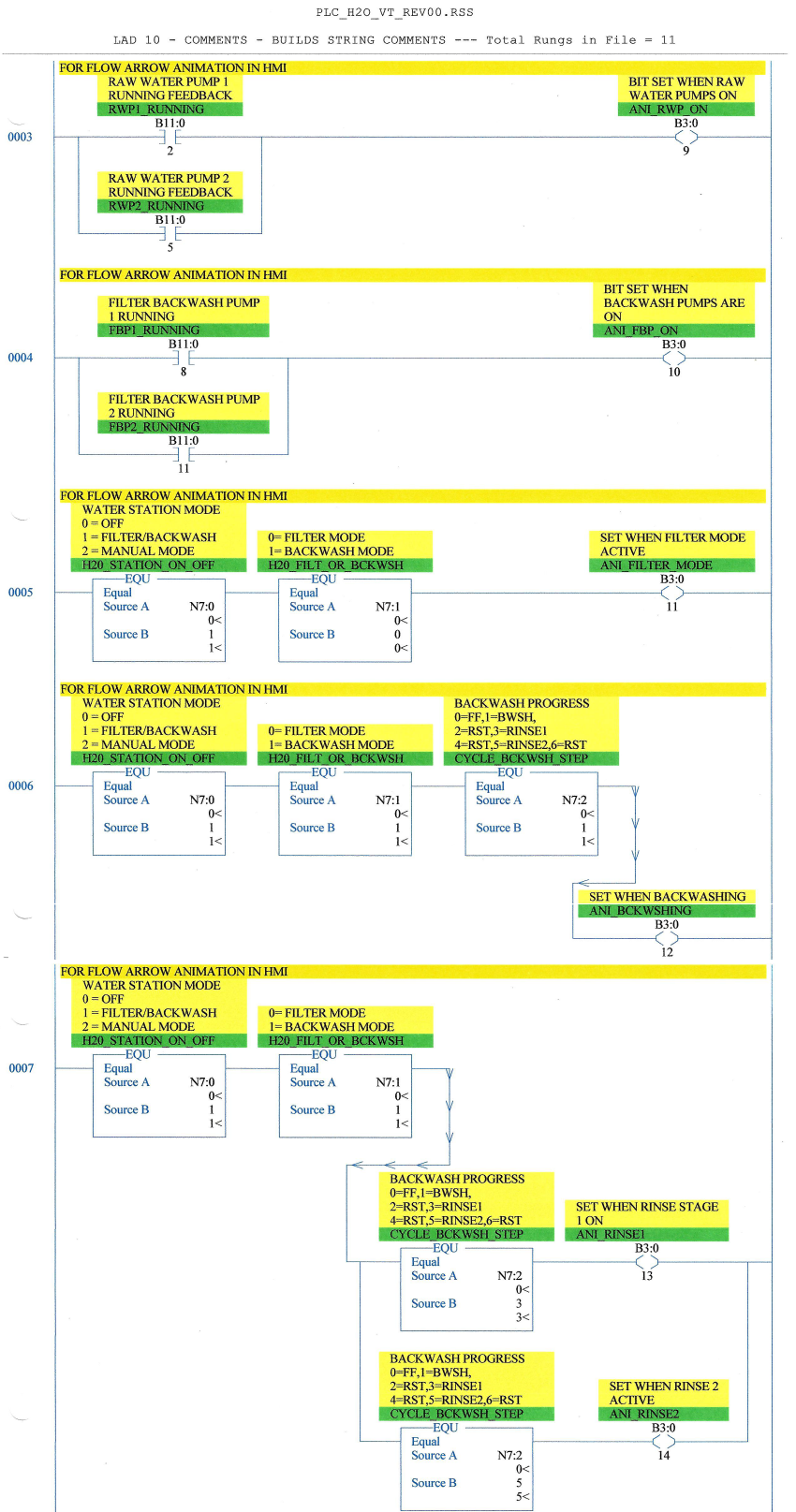

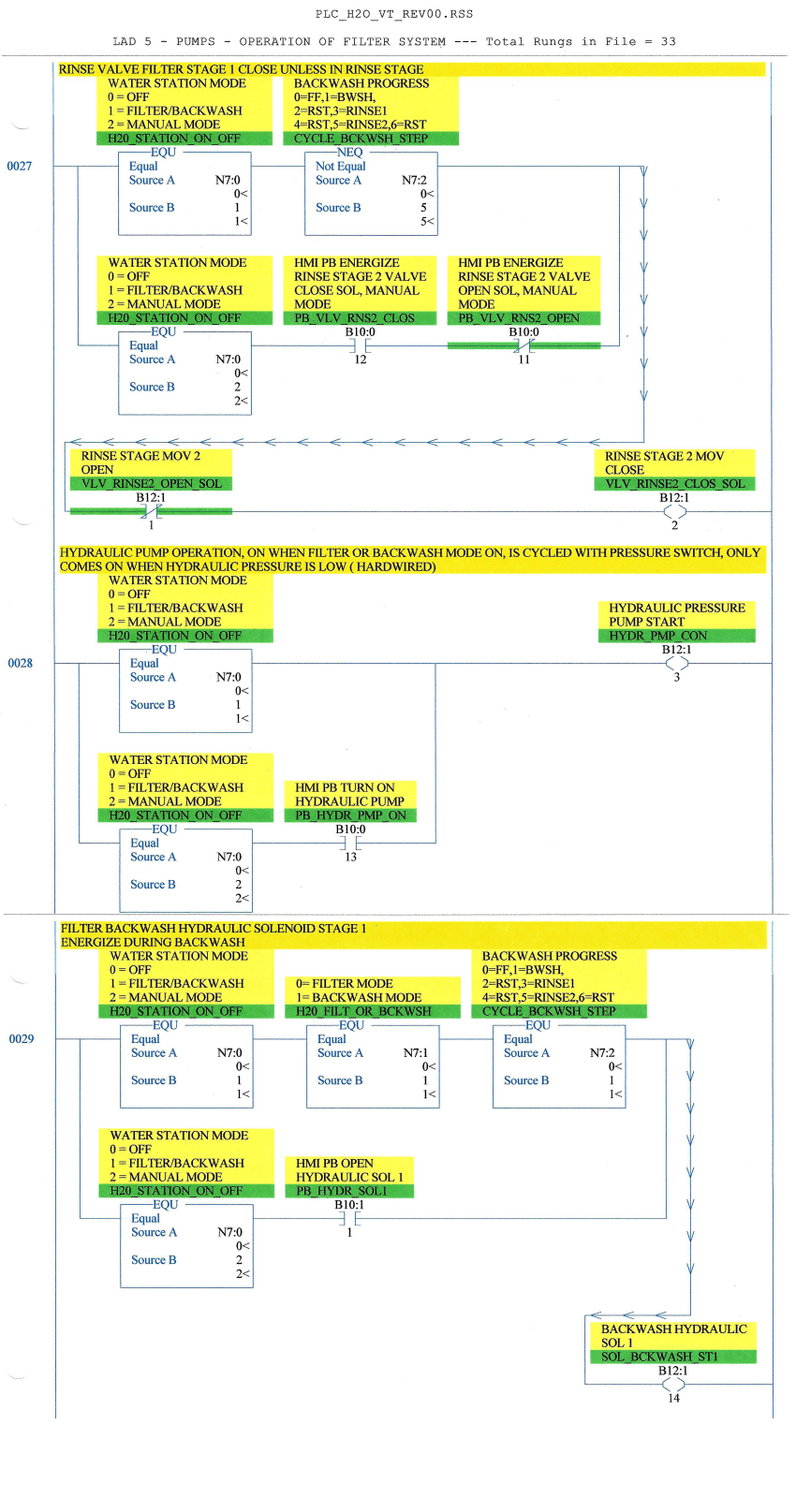

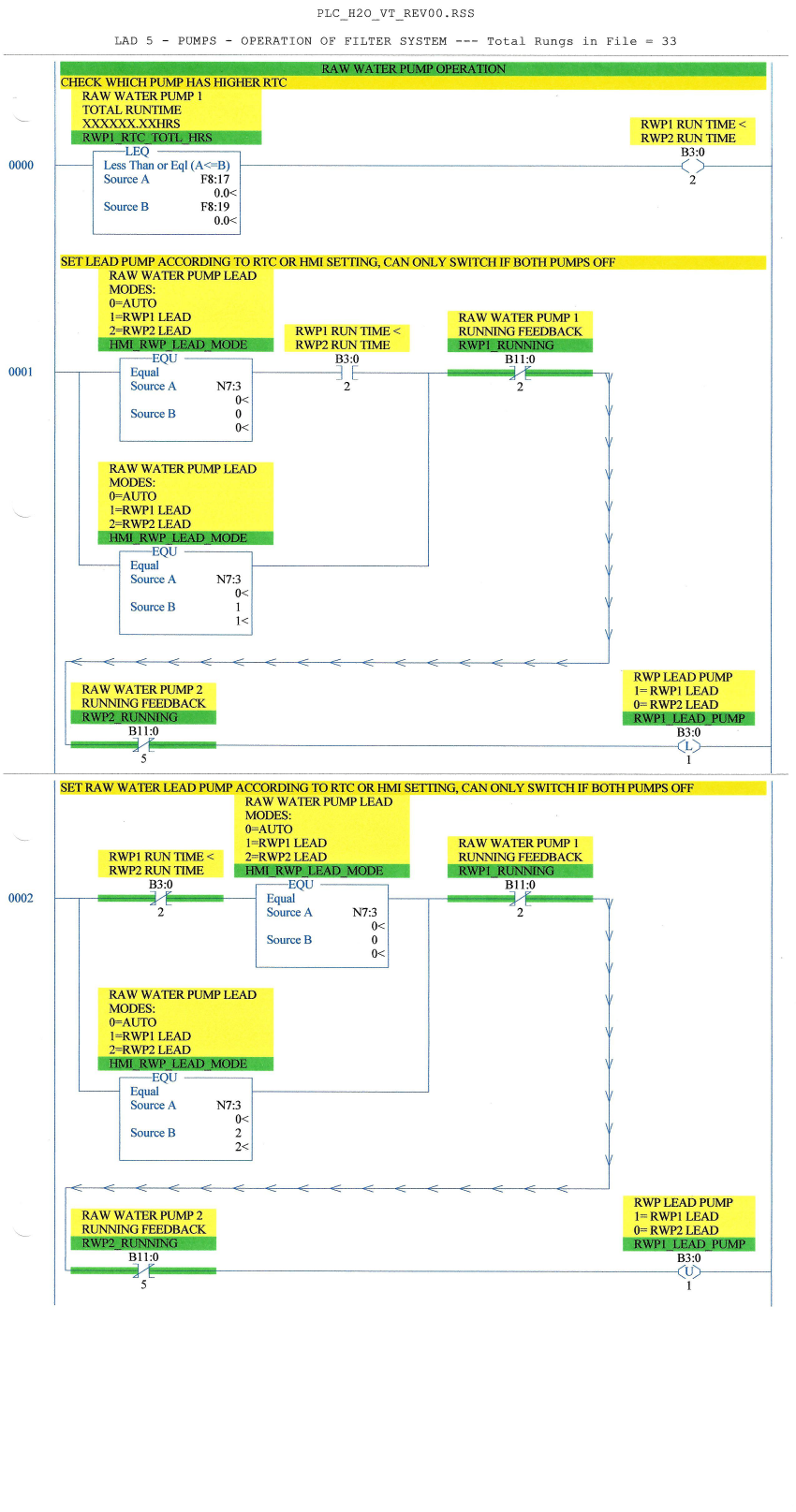

In our Panel shop we build, design, and test electrical control panels for the water and waste water market as well as for our industrial clients. Our panels are UL 508A listed and marked.

In our Panel shop we build, design, and test electrical control panels for the water and waste water market as well as for our industrial clients. Our panels are UL 508A listed and marked.